Atlas Copco LRP VSD+ 700 – 1000 m³/h

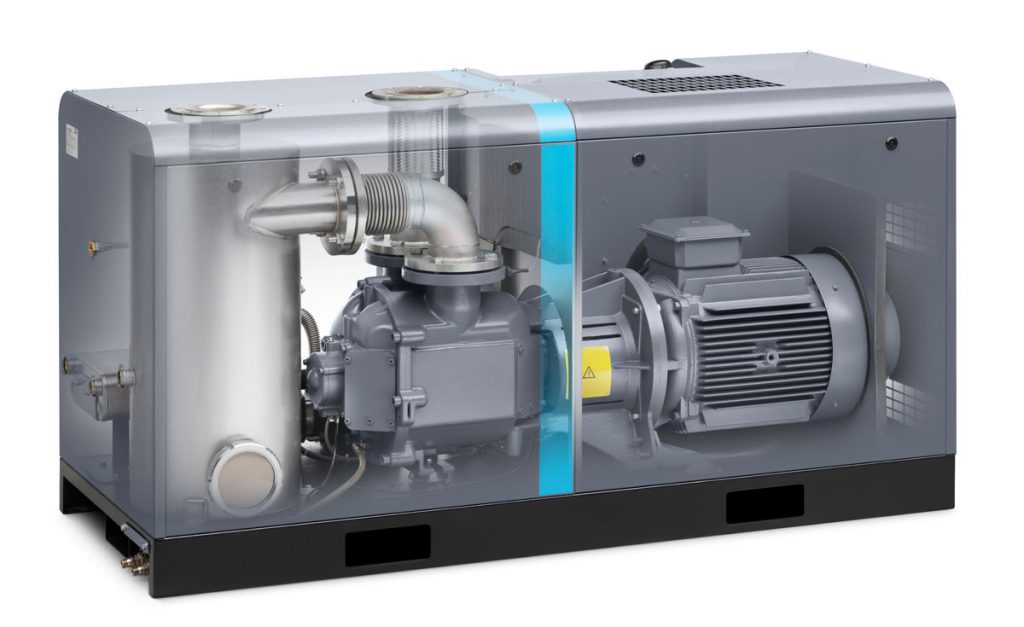

Atlas Copco LRP VSD+ pumps are intelligent liquid-ring vacuum pumps with variable speed drive (VSD). They are perfectly suitable for the most difficult processes and applications in which dirt, moist and extreme steam loads are involved and in which even liquid or solid parts can make their way into the pump. On top of that, they are among the smallest in terms of storage space in comparable pumps due to their compact Plug&Play design.

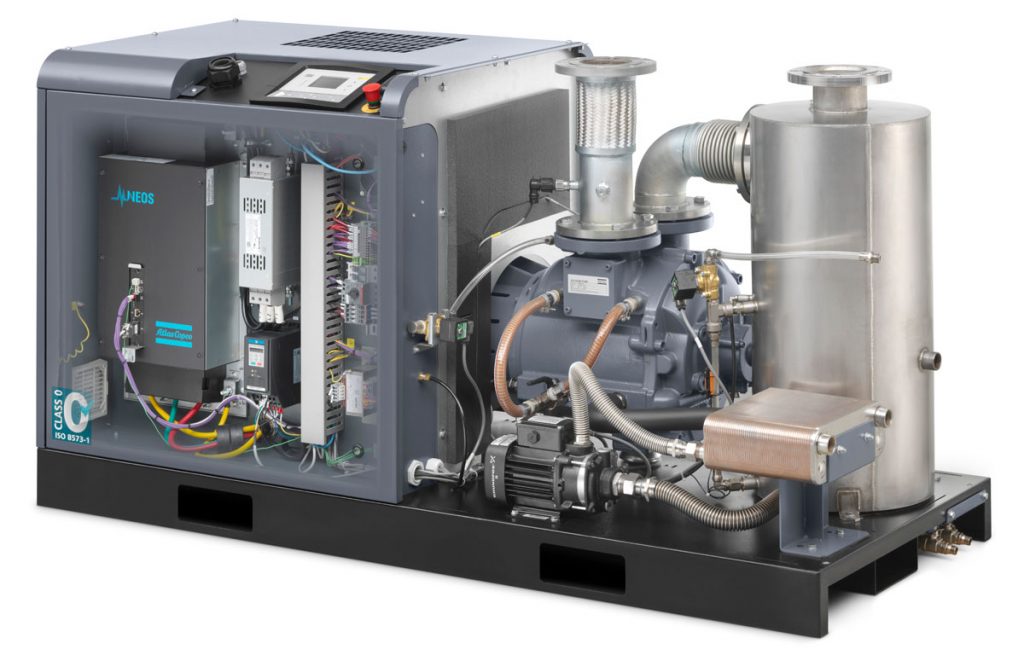

Atlas Copco’s many years of experience in compressors find expression in the setup of the system’s control and VSD regulation. The pump’s regulation, inlet, outlet and main cable port can be found on the upper surface, thus contributing to an extremely user-friendly installation. Information on all kinds of data including the pump’s operating status and vacuum setpoint control can be retrieved from the MKV-Elektronicon® regulation contained in the standard delivery package. At the same time, several LRP-VSD-vacuum pumps can be monitored and controlled via Atlas Copco’s ES control system.

An LRP pump constitutes a state-of-the-art vacuum solution achieving an ideal energy efficiency – thanks to its two variable speed control regulations. This is a unique feature on the market for liquid-ring vacuum pumps. While one of the two speed control regulations is in charge of maintenance and adjustment of the required vacuum levels through the vacuum setpoint control, the other one is responsible for the water circulation pump, leading to an optimized water flow and stable vacuum levels.

Maintenance works can be performed easily and quickly thanks to a smart setup allowing for horizontally-oriented operability and handy access opening. As a special feature, the pump disposes of Automatic Seizure Prevention, which prevents the pump element from being stuck after a longer period of pump inactivity, thus achieving an even more extensive durability.

An entirely oilfree vacuum is required wherever supreme air quality is crucial for both the process and the final product. Naturally, in cases where vacuum comes into contact with food or medicaments, our customers need absolute safety. This can be guaranteed by our certified Class 0 products.

Areas of application:

- Chemical industry

- Metal processing

- Tile press

- Cement products

- Food production

- Mining

- General manufacturing

- Paper products

- Automobile industry

- Electricity and supply companies

- Petroleum industry

- Oil and gas

- Plastic

- Textile industry