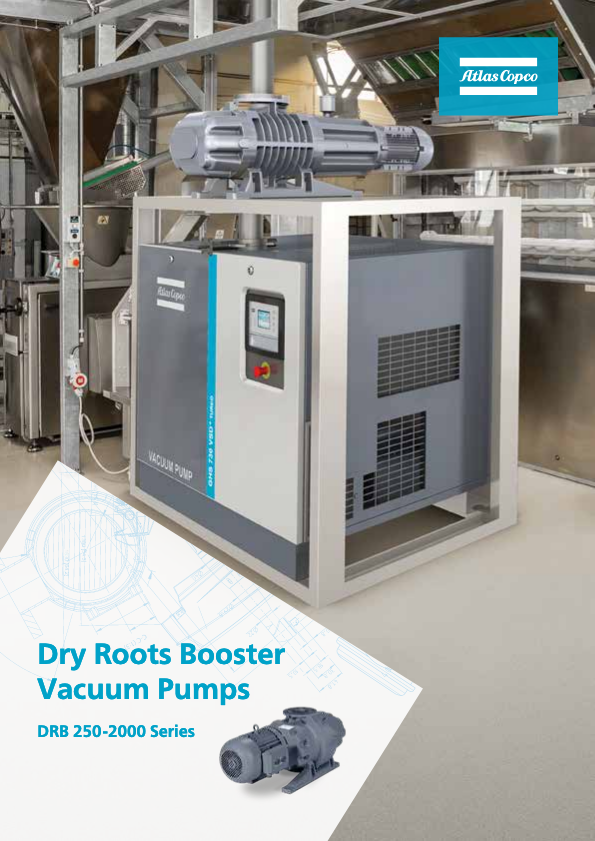

Atlas Copco DRB 250 – 2000 m³/h

Atlas Copco DRB pumps are mechanical Roots pumps based on the Roots principle and perfectly suitable for applications in which high volume flow rates are required. In this pump one Roots rotor connected with a torsionally flexible claw coupling is powered directly by the engine, while the second Roots rotor is driven one-to-one by the first Roots rotor via a synchronisation gearbox, causing it to run in the opposite direction.

As a basic requirement, this pump must be operated with a backing pump able to create a high pressure difference to the atmospheric pressure. Depending on the process or the required final pressure, a single- or two-stage rotary vane pump or screw pump (GHS, DHS) are commonly applied. If a DRB pump is linked with a dry screw pumps such as the DHS, an entirely oil-free pump mechanism can be achieved. The tried and tested shaft seals ensure that no oil reaches the pump’s suction chamber. This way, the performance of the Roots pump can be maintained during applications that require a maximum of cleanliness. Furthermore, an accumulation of particles can be avoided on the rotor blades and end faces that show very little tolerance.

The minimal gap dimensions and manufacturing tolerances, the dynamically balanced rotors and the well proven coupling minimize maintenance requirements and ensure a smooth and low-vibration pump operation.

Areas of application:

- Vacuum metallurgy

- Vacuum packaging

- Drying and degassing

- Vacuum distillation

- Vacuum furnaces

- Thin-film coating

- Space simulation

- Vacuum impregnation

- Vacuum welding and brazing

- Deep-freeze

- Vacuum chambers